Workers are dying

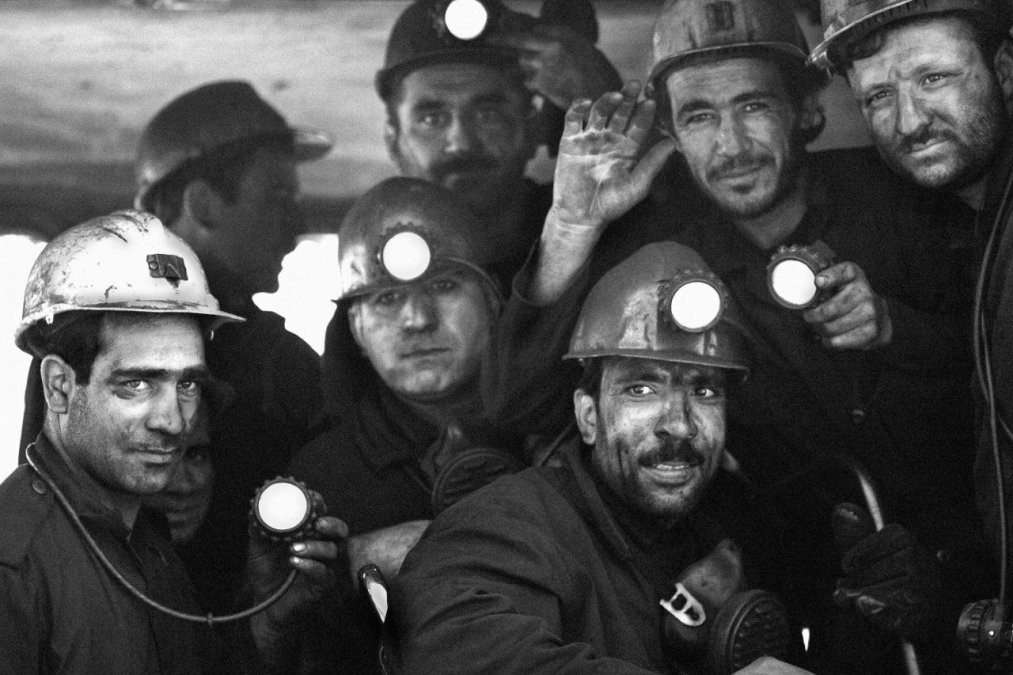

Workers are dying. The bodies of 18 other workers in Block C of the coal mine need to be removed, but due to the high volume of methane gas, rescuers have not yet been able to enter Block C of the mine. Coal mine accidents are devastating for operations and the lives of miners. Methane and other flammable or toxic gases are a reality of life and death in coal mines.

Gas explosions are the most common cause of these accidents. Methane explosions can ignite more powerful coal dust explosions. Coal can easily catch fire or start burning. In each of the coal mine accidents, trapped miners are killed due to explosions, fires, or smoke filling the room. In mines with poor ventilation, miners have lost their lives by inhaling gas without any explosions.

The roof or walls of coal can collapse and trap miners. Some of the worst conditions have been caused by mine flooding, drowning of workers, and failure of tailings dams, with pollution from liquid toxic mining waste wreaking havoc downstream and in the environment. Coal mine explosions cause the most casualties in mining.

There are two main types of coal mine explosions: methane and coal dust. A methane explosion occurs when a buildup of methane gas comes into contact with a heat source and there is not enough air to dilute the gas below its explosion point. Similarly, fine particles and coal dust at the right concentration can also be explosive when they come into contact with a heat source. Hybrid explosions, consisting of a combination of methane and coal dust, can also occur. Methane forms as a byproduct of coal. Methane absorbed in coal is released during coal extraction or from surrounding sources above or below the coal seam through fractures created by the coal extraction process.

At 7:30 PM on Sunday, September 3, 2023, a gas buildup explosion in one of the tunnels of the Eastern Alborz company’s mine led to the death of six miners in the Tazareh Damghan coal mine explosion. This incident once again drew attention to the safety of these mines and the very nature of this type of mining in the country. Gas is transferred out of the mine during workers’ operations using pipes made of plastic sacks.

This gas remained in the tunnel air overnight, and with the accumulation of gas and a spark from the pickaxe activity, an explosion occurred in the mine. Two locomotive drivers loading coal below and one worker under the extraction workshop bunker, along with three extraction workers, were trapped under the debris. This was the second deadly incident in this mine in the past two years.

Two years ago, two miners were also killed. On May 3, 2017, when about 80 workers were working in the tunnels of the Zemestan Yurt coal mine at a depth of 1000 meters underground, methane gas accumulated in one of the workshops exploded due to a spark from a locomotive battery inside the mine, causing the mine walls to collapse. The first message from rescuers who arrived at the scene to save the workers was that considering the high concentration of carbon monoxide and smoke from the explosion, all trapped workers inside the mine had died. A week later, the death toll reached 43. Two people were crushed under the mine debris, 10 were thrown by the force of the explosion, and 31 suffocated from carbon monoxide gas.

The country’s confirmed coal reserves are estimated at about 11 billion tons. The main use of coal in Iran is limited to steel production factories that use the blast furnace method for steel production. Most of Iran’s exploration dates back to previous decades. Iran’s coal seams are located at depths of 100 to 300 meters and have a thickness of 50 to 100 centimeters. Due to the high presence of methane gas, the risk of explosion in these mines is very high, increasing ventilation costs. Coal production in the country’s mines is done using traditional extraction methods and outdated equipment and machinery, and the use of outdated technology reduces labor productivity.